In the modern industrial world, many organizations face a significant challenge: critical products with no engineering documentation. This may include old equipment with lost drawings, imported parts without technical data, or assemblies that were never properly documented.

In such cases, reverse engineering offers a proven solution. It enables full and accurate documentation recovery, restores products to serial production, and preserves essential engineering knowledge.

What Is Reverse Engineering and When Is It Needed?

Reverse engineering (also known as back engineering or inverse engineering) is the process of taking an existing physical product — a mechanical part, assembly, or electromechanical component — and reconstructing its engineering documentation even when no original technical data exists.

Unlike forward engineering, which starts from an idea and progresses toward a finished product, reverse engineering works in the opposite direction: from the final product back to the documentation and engineering understanding.

When Do Organizations Need Reverse Engineering?

- Loss of original documentation: when drawings, 3D models, or specifications have been lost over time or never existed.

- Imported products: components or assemblies supplied by a foreign manufacturer without adequate documentation, which the organization now needs to produce independently.

- Preservation of engineering knowledge: when critical know-how resides only with key personnel and must be formally documented.

- Reinstating serial production: when the production of a discontinued product is to be resumed.

- Localization: when shifting from offshore to local production, or transferring manufacturing to a new supplier that requires full documentation.

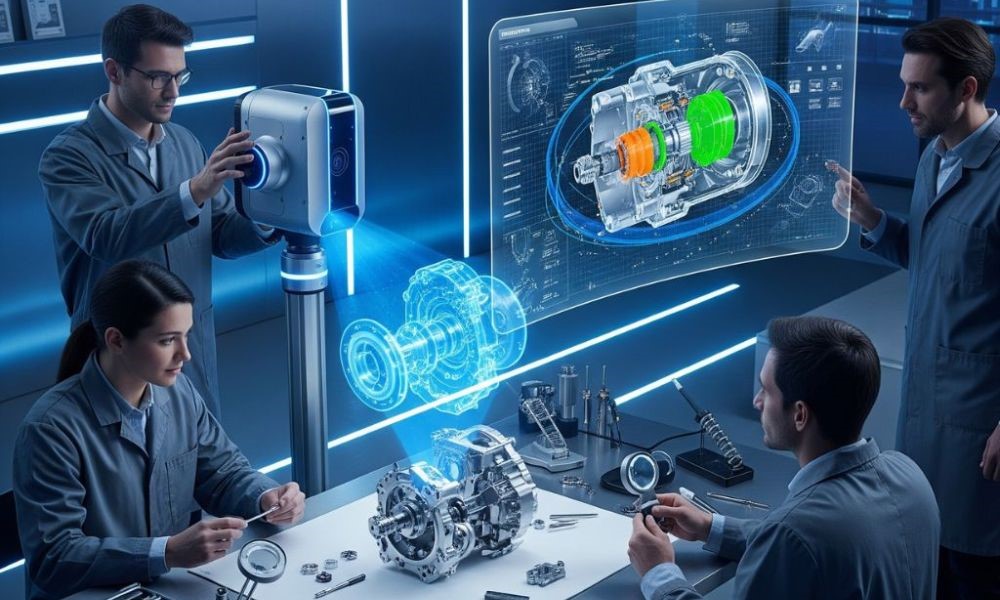

The Professional Process: From Scanning to Production

High-quality reverse engineering requires a systematic and professional approach that combines advanced technologies with deep engineering expertise.

Precise Scanning and Data Capture

The process begins with advanced 3D scanning technologies that capture the exact geometry of the part or assembly. The scan is performed at high resolution, ensuring that every detail, down to the smallest screw, is recorded accurately.

Assembly Analysis and Disassembly

After scanning, the structure is carefully analyzed: how components connect, assembly methods, required tolerances, and the materials used.

3D Modeling and CAD Creation

Collected data is translated into precise 3D CAD models using professional design software. This stage involves true engineering work, not merely replicating form, but applying Design for Manufacturing (DFM) principles to optimize the model for future production.

Complete Product Documentation

The final output is a comprehensive Product Dossier that includes detailed manufacturing drawings, full technical specifications, a bill of materials (BOM), assembly instructions, and quality and testing requirements.

Prototype Production and Validation

Before mass production, a prototype is manufactured to validate the documentation, verify functionality, and ensure that all dimensions and tolerances meet original requirements.

This step is crucial to prevent costly errors during full-scale production.

Beyond Reconstruction: A Complete Value Chain for the Customer

The true value of professional reverse engineering lies not only in documentation recovery but in providing an end-to-end solution:

- Design and manufacturing drawings: full product documentation optimized for manufacturing efficiency and cost-effectiveness.

- Procurement and supply: sourcing standard components, raw materials, and custom parts required for production.

- Precision manufacturing: executing production according to the reconstructed models and drawings using advanced manufacturing methods.

- Complex assemblies: performing sub-assembly and full system assembly, including calibration and functional testing.

- Comprehensive quality assurance: dimensional, functional, and compliance testing throughout the entire process.

Proven Business Advantages

- Returning products to serial production: restoring availability of discontinued or obsolete parts.

- Knowledge preservation: converting critical know-how held by individuals into formal, accessible documentation.

- Shorter timelines: re-engineering an existing product takes weeks instead of the months usually required.

- Improved reliability and quality: identifying and enhancing weak points in the original design.

- Supplier flexibility: eliminating dependency on a single vendor and maintaining full control of the supply chain.

Forward Engineering vs. Reverse Engineering

| |

Forward Engineering |

Reverse Engineering |

| Starting point |

Idea or business need |

Existing physical product |

| Process flow |

Idea → Design → Production |

Product → Analysis → Documentation |

| Development time |

Long (months to years) |

Shorter (weeks to months) |

| Cost |

High (new development) |

Lower (existing product) |

Practical Applications Across Industries

Reverse engineering is widely applied across numerous industries, each with its own unique challenges:

- Defense and military: reproducing spare parts for legacy systems, adapting assemblies to new specifications, and maintaining critical equipment no longer supported by the original supplier.

- Medical devices: recreating discontinued components while meeting strict regulatory and quality standards (FDA, CE), ensuring precision and complete documentation.

- Aerospace: documenting old aircraft and helicopter parts, producing replacements, and ensuring compliance with the highest safety and reliability standards.

- Electronics: reconstructing printed circuit boards (PCBs), electronic components, and electromechanical assemblies, essential when the original manufacturer is no longer in operation.

- Traditional industries: heavy machinery, industrial vehicles, and long-serving production equipment requiring maintenance or reproduction after decades of service.

Frequently Asked Questions

How long does the reverse engineering process take?

It depends on product complexity, from a few days for a single simple component to several weeks for a complex assembly.

Can reverse engineering be done without any documentation?

Yes. Using advanced 3D scanning and engineering expertise, complete documentation can be recreated even when no original data exists.

What level of accuracy can be achieved?

Modern scanning technologies reach accuracies of tens of microns (0.01 mm or less), sufficient for even the most demanding industrial applications.

When do companies use reverse engineering?

Organizations use it to recover lost documentation, resume discontinued production, preserve engineering knowledge, or transition from external suppliers to in-house manufacturing.

Can the product be improved during reverse engineering?

Absolutely. Beyond reproduction, the process enables improvements such as better materials, more efficient manufacturing methods, or refined design.

Is reverse engineering suitable for small companies?

Yes. The method suits small, medium, and large organizations alike. It is a cost-effective alternative to full redevelopment or supplier dependency.

From Missing Documentation to Business Opportunity

Professional reverse engineering transforms a challenge — lack of engineering documentation — into a true business opportunity.

It delivers not only restored drawings but a complete turnkey solution, from part reconstruction and full product documentation to high-quality serial manufacturing, assembly, and comprehensive quality control.

Y. Sherman offers advanced reverse engineering capabilities, combining decades of experience with cutting-edge technologies.

We provide customers with a full turnkey service, from initial scanning to the fully documented finished product. This enables organizations to turn missing information into opportunity and achieve genuine technological and operational independence.

Interested in restoring documentation or returning products to serial production?

Contact I. Sherman for professional consultation and a tailored solution.